Consulting and Design

Knowledge Base of Physical Security and Process Safety Mitigation Measures and Products

Navigating the vast array of safety and physical security products available today can be daunting. Whether you’re a commercial, government, or industrial entity, determining the best solution for your needs can be challenging.

At Stone Security Engineering, we specialize in security and safety engineering, offering a comprehensive suite of services to address intentional or accidental hazards such as explosions, fires, and toxic events.

We excel in blast and physical security mitigation measures and products. Our engineers are well-versed in these technologies and are equipped to assist clients in comparing and selecting the most effective solutions.

We strive to provide objective guidance and support throughout the decision-making process. Whether you’re evaluating blast-resistant materials or considering security enhancements, Stone is here to help you navigate the complexities of the marketplace and find the best solutions for your organization’s needs.

Security Design Analysis

Stone Security Engineering collaborates closely with design teams to integrate various security engineering requirements into overall project design. This includes aspects such as anti-terrorism/force protection (AT/FP), blast resistance, progressive collapse prevention, ballistic protection, and measures against forced entry.

We offer support and recommendations to landscape architects, architects, and structural and MEP (mechanical, electrical, plumbing) engineers to ensure that necessary security measures are seamlessly incorporated into the design process.

Our expertise extends to addressing a wide range of threat scenarios, both within and outside buildings, and devising solutions to enhance their resistance to progressive collapse.

We are well-versed in applying government criteria documents and manuals such as the PB-100, the Interagency Security Committee Security Design Criteria for New Federal Office Buildings and Major Modernization Projects, the DoD UFC 4-010-01 Minimum Antiterrorism Standards for Buildings, the DoD UFC 3-340-02 Structures to Resist the Effects of Accidental Explosions, GSA Progressive Collapse Guidelines and the DoD UFC 4-023-03 Design of Buildings to Resist Progressive Collapse (updated in July 2009).

“Any building, regardless of its complexity, can provide physical security mitigation measures without jeopardizing the architectural design. You just need to apply creativity and understand the architectural vision.”

– Arturo Montalva, Principal and Vice President, Technical Director

Safety and Design Analysis

Stone Security Engineering works closely with ammunition manufacturing facilities, energetics laboratories, and similar installations that create, use, and store explosive and energetic material are required to meet explosives safety siting standards to protect personnel and limit hazardous effects in the event of an accidental detonation.

Our team boasts extensive expertise in preparing Quantity-Distance (Q-D) or risk-based Explosion Safety Site Plans, following guidelines such as DoD 6055-09M, DDESB standards, or industry equivalents.

We conduct thorough evaluations of potential explosion, fire, and fragmentation hazards on-site, devising feasible measures to mitigate these risks. From conceptualization to final design drawings and construction support, we guide clients through the implementation of these safety measures.

Our team also possesses significant experience in hazard assessment and mitigation across various industries, including chemical, petroleum, and pharmaceutical plants. Leveraging this expertise, we offer tailored solutions to industrial clients to mitigate blast, fragment, fire, and toxic hazards.

We also work with companies in designing prevention, mitigation, and controls in order to detect, shut down, and prevent the release of hazardous materials, ensuring compliance with Process Safety Management regulations and industry standards such as API, NFPA, and CCPS. Our scope of work encompasses a variety of structures within industrial facilities, including control rooms, containment areas for chemical processes, administration buildings, laboratories, and other permanent or temporary structures.

Planning

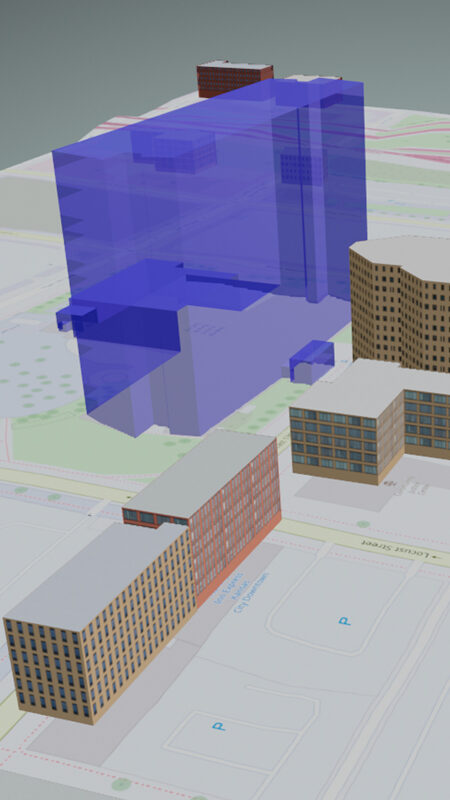

Taking into account counter-terrorism or process safety and hazard mitigation measures during the master planning and project planning stages allows the project team to integrate risk reduction from the very beginning, resulting in more efficient, sophisticated, and cost-effective strategies and solutions.

We collaborate with project teams throughout the planning process, offering guidance on site layout, building materials and massing, and building program layout. Work on these projects typically commences with a “Physical Security or Process Safety 101” class for team members to familiarize them with the implications related to their respective disciplines.